Furnace Pressure Switch is Stuck Open? (We Have A Fix)

Your furnace is a complicated piece of machinery. There are so many components involved to ensure that your home stays nice and toasty without so much as a second thought. But those various components can mean that things will go wrong from time to time.

A malfunctioning switch, a broken pressure switch hose, or a clogged vent can cause a pressure switch to remain open. Some problems such as a broken pressure switch hose or a clogged vent happen during normal use. A malfunctioning switch is usually due to the age of the switch. Regular maintenance helps prevent such malfunctions in your HVAC system.

Understanding how the pressure switch and the inducer work together to protect your family and home is critical. A failure in this system can cause toxic gases to be introduced into your home. Regular maintenance is essential to keep your HVAC system operating safely

Do You Need a Furnace Repair Contractor?

Get free, zero-commitment quotes from pro contractors near you.

What Does the Pressure Switch Do?

The purpose of the furnace’s pressure switch is to act as a safety feature. Basically, it makes sure that the gases being used to create combustion leave your home. When gases are reintroduced into your home, the process is known as backdrafting.

Backdrafting is very dangerous. It takes the gases that are created during combustion like carbon monoxide and introduces them into the air supply in the home. Moreover, backdrafting can cause potential explosions in the heat exchanger, which is the core of the furnace.

Why is the Pressure Switch Stuck Open?

Generally speaking, there are three reasons that the pressure switch on your furnace will stay stuck open. When troubleshooting the problem, look for these three signs.

Damaged or Disconnected Pressure Switch Hose

The pressure switch uses the hose to tell if the inducer motor is doing what it is supposed to be doing. When the hose gets disconnected or damaged with things like holes and cracks, it can result in the pressure switch getting inaccurate readings and getting stuck open.

Finding issues with the switch hose can be difficult if you don’t know what to look for. Even if you can visually locate the issue, reattaching the hose can be challenging.

You should be able to determine if the switch hose has been disconnected from the inducer draft blower. Performing the repair, however, can be challenging without the proper level of knowledge and experience. Calling in a pro is probably the best course of action here. They can perform the repair or replacement quickly and relatively cheaply.

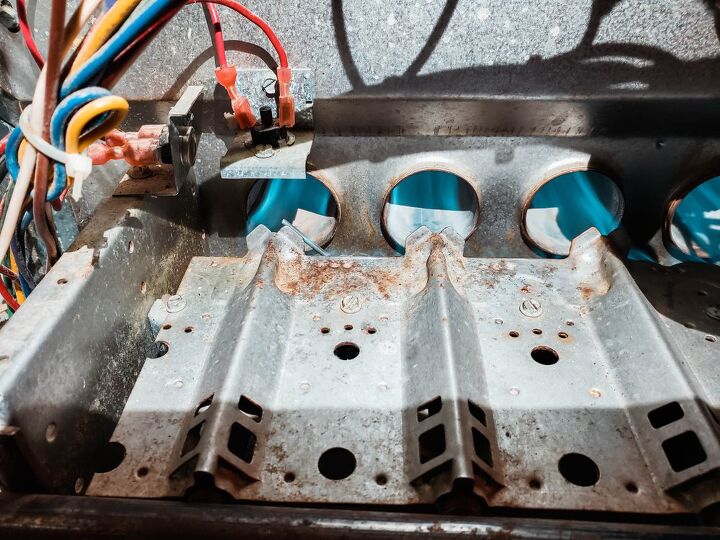

Venting is Obstructed

When the flue pipe gets clogged or obstructed, the system can’t get rid of combustion gases. A build-up of those gases can keep the switch open. This is a fairly common occurrence since flues can get clogged up with dirt, leaves, and other debris. They can even freeze up during the winter.

When checking the venting, start with the flue pipe. You can generally expect to find it on the roof for conventional furnaces or in a white PVC pipe that is on the side of the house in other instances. If you can see and reach the debris, clear it away and try the furnace again.

If the issue doesn’t resolve itself, keep trying to find and clean out debris. Should that still not work, you may need a service technician to come out and perform a more thorough cleaning. It isn’t super common for debris to get clogged way down in the venting, but it also isn’t unheard of.

Malfunctioning Switch

If you have already done your due diligence and don’t notice any debris clogging up the flue pipe, move on to the hose next. Should the hose be connected and not showing any signs of damage, it could be that the pressure switch is the issue.

Having a digital multimeter on hand can be a helpful tool. You can use it to check the pressure switch to verify that it is working properly. While this is a repair that can be done by amateurs, it isn’t recommended. Performing the wrong fix can result in potential safety issues and long-term damage to the furnace.

When it seems like the pressure switch is malfunctioning, the best bet is to bring in a certified technician. They can identify the problem in short order and implement a fix safely and in a timely manner.

Furnace Pressure Switch Troubleshooting

How Do You Prevent Backdrafting?

Backdrafting can be extremely dangerous for the safety of your home and your family. So, it only makes sense that preventative measures are taken to prevent it from happening. The pressure switch is preeminent in this process.

Here is how the pressure switch keeps backdrafting from occurring:

- Gases created. When the furnace fires up, the furnace creates gases, some of which are poisonous. This is part of the heat creation process also known as the combustion process.

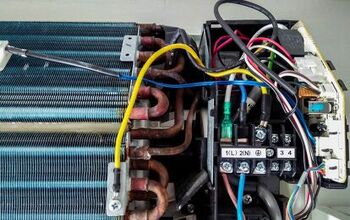

- Inducer motor. Next, the draft inducer motor works to suck out those gases from the heat exchanger. It takes those gases and then distributes them out of the home through the flue pipe.

- Pressure switch. The pressure switch watches the inducer to ensure that it is moving those gases out of your home. When the draft inducer is working as it should, the pressure switch then completely closes the circuit (turns on).

- Issues. When there is an issue with the draft inducer motor, the pressure switch will then open or turn off. The furnace then shuts down to prevent ignition since there could be a buildup of those dangerous gases.

When the pressure switch stays open, it indicates that there is either an issue with the switch or the inducer. Troubleshooting the issue or calling in a professional can help achieve the necessary repairs to get the system working again.

Different Types of Pressure Switches

Not all pressure switches are created equally. There are slightly different designs depending on the type of furnace that you have. Understanding the different furnace pressure switches can help you identify the troubleshooting that needs to be done.

- Single-stage conventional. There is one pressure switch in a single-stage conventional furnace. That single pressure switch has a single hose as well. The hose leads into the draft inducer body.

- Single-stage condensing. The difference between this one and the former is that there are two hoses on the pressure switch. One of the senses pressure the burner/inducer enclosure. The other sense that there is proper venting pressure in the condensate collector box.

- Two-stage. These can but don’t necessarily have to have two pressure switches. In modulating furnaces, there may even be three switches.

Understanding the type of pressure switch that you are dealing with is important. Even if you don’t plan on implementing a fix for your pressure switch, you can provide helpful information to the HVAC technician.

How Do You Test the Pressure Switch?

Should you think that the pressure switch is potentially faulty, it can be helpful to test it before making the next move. But how do you test the pressure switch? Use this step-by-step guide to perform the test. At worst, you can relay the information to the technician when they come out. That will save them time and you money in the long-run.

There is one important thing to remember. If you do not feel comfortable or confident implementing the repair yourself, do not try it. You can make the issue worse and do damage to the other components of your HVAC system. When in doubt, bring in professional help.

Do You Need a Furnace Repair Contractor?

Get free, zero-commitment quotes from pro contractors near you.

Testing the Pressure Switch

- Turn off the power. As is the case with any troubleshooting in your furnace or AC, turn the power off first. You can do this by turning off the disconnect switch if there is one. Should there be no disconnect switch, you will have to turn off the breaker leading to the furnace at your main breaker box.

- Check the switch hose. Take off the access panel at the front of the furnace and check the hoses that are connected to the pressure switch. Make sure they are in good condition and that they are properly connected. Should you notice damage or cracking, replace the hose.

- Check for obstructions. So long as there is no damage, remove the hose carefully. Make sure that there are no obstructions on the inside. It is important that you do not blow into the hose while it is connected. Doing so could potentially damage the pressure switch.

- Check the hose port. Next, grab a flashlight and look inside of the hose port located on the pressure switch. Look for any potential obstructions, removing debris using a small instrument of your choosing. Just be careful to not poke the switch body and don’t blow into the inlet. Reinstall the hose when done.

- Check furnace cover. Take a look at the furnace cover, inspecting the vent slots to make sure they’re clean. If not, give them a quick cleaning.

- Vent blockage. Your vents could also be at fault. Check to see if the vent pipe is blocked. The PVC pipe generally extends out of your roof or a sidewall on your home.

- Switch resistance. Disconnect the wires and touch them to your multimeter to test them out. You are checking to see the viability of the switch.

Keep Your Family Warm and Safe

In the end the comfort and safety of you family and your home are the priority concerns. Maintaining your HVAC systems in peak operating condition is the key to this goal. If the pressure switch on your HVAC system isn’t working properly, you must diagnose the reason and make the appropriate repairs.

Ryan Womeldorf has more than a decade of experience writing. He loves to blog about construction, plumbing, and other home topics. Ryan also loves hockey and a lifelong Buffalo sports fan.

More by Ryan Womeldorf

![The 5 Best Angle Grinders – [2022 Reviews & Buyer's Guide]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9071326/the-5-best-angle-grinders-2022-reviews-buyer-s-guide.jpg?size=350x220)

![10 Best Scroll Saws for 2022 [Ultimate Reviews & Buyer's Guide]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9070684/10-best-scroll-saws-for-2022-ultimate-reviews-buyer-s-guide.jpg?size=350x220)